Lawrence Memorial Hospital Sterile Processing Addition

One of the most common challenges P1 Group faces on the job is working around unforeseeable conditions, such as weather or busy facilities that can’t be shut down for construction. In many instances, our field teams have to think quick to come up with rescheduling solutions and demonstrate extreme care working around staff and facility users, sometimes in critical environments.

Such was the case with the recent 8,000 sq. ft. sterile processing addition to Lawrence Memorial Hospital (LMH).

P1 Group worked with General Contractor McCownGordon, architect ACI Boland, and engineer Henderson Engineers on the electrical project which was completed in late September, 2019.

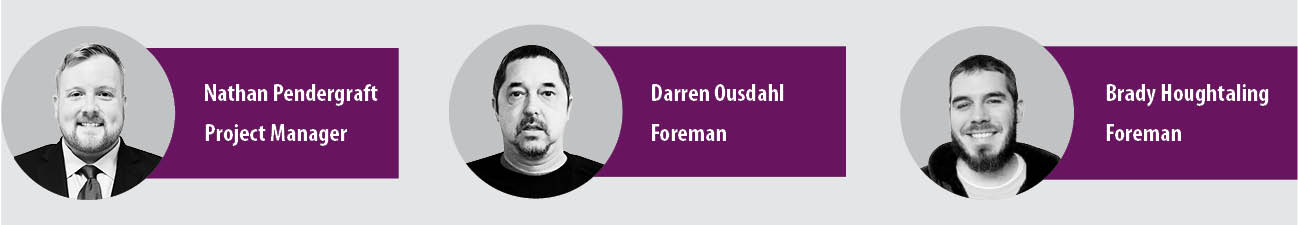

“The project had weather challenges in the beginning which impacted schedule early on,” P1 Project Engineer Nathan Pendergraft sad. “Fortunately our trade coordination meetings helped us meet and exceed key milestones despite the challenges.”

The team also had to work around LMH’s surgery schedules, so the project team performed strategic planning and phasing to accommodate.

The project included electrical construction and fabrication for the installation of more than 100 light fixtures and several thousand feet of conduit and wire in the new addition.

“Foremen Darren Ousdahl and Brady Houghtaling’s extensive knowledge of the LMH Facility was a key contribution to providing solutions to challenges that arose,” Nathan said. “Overall, the project was a success due to the team’s open lines of communication between the office and the field.”

P1 Group’s team effort did not escape the attention of the project GC, either. Here’s what McCownGordon Senior Project Manager Tyler Stotler had to say in a letter to P1 Group CEO Smitty Belcher:

“On behalf of McCownGordon, I would like to thank you for your company’s performance on the LMH Sterile Processing & Distribution Addition. Your project team’s attitude towards safety, attention to detail, and commitment to quality helped to ensure this project was a success for the entire team.

Darren Ousdahl’s experience and knowledge of the hospital was helpful and instilled confidence in our team from the hospital’s perspective. Darren was professional and friendly. Darren took time out of his day on multiple occasions to help me wrap my head around detailed RFls and understand complex issues.

Nathan Pendergraft’s documentation and organization was appreciated as it related to submittals, procurement, and change management. Nathan attended nearly every sub-progress meeting which made the difference with field-to-office communication.

Brady Houghtaling was detail oriented, timely, and maintained good communication with our team throughout. This made the transition at the end of the project a smooth one. Brady also went out of his way to help us complete low voltage door controls at the end of the job.

We value our strong relationships with trade partners who perform exceptionally well, and we look forward to working with your team on future projects.”

Another show of P1 Group’s staunch commitment to safety, communication, quality, and integrity. Great job, guys!

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.