Expanding to the East: Project Profile on Nestle Purina Project Conan

St. Joseph, MO, has a rich history steeped in manufacturing that includes companies such as Nestlé Purina Petcare, one of the leading manufacturers of pet food in the world.

P1 Project Managers Shawn Conz, Jason White, and Cris Ray have been working in the electrical trade in St. Joseph for the duration of their careers. The three joined P1 when the company expanded into St. Joseph in 2014, and Nestle came on board as a customer as well.

The St. Joseph team has developed a good working relationship with Nestle over the years.

“Nestle appreciates the quality of work P1 does for them, so they typically ask us to bid upcoming projects,” Shawn said.

In recent years, Nestle developed Project Conan - upgrading the capacity of several plants across the country – to address a nationwide pet food shortage.

Included in those plants is one in Mechanicsburg, PA, where the P1 team is currently working.

“There is a 30 percent shortage of dog food in the US, which is why Nestle is putting significant investment toward increasing production nationwide,” Shawn said.

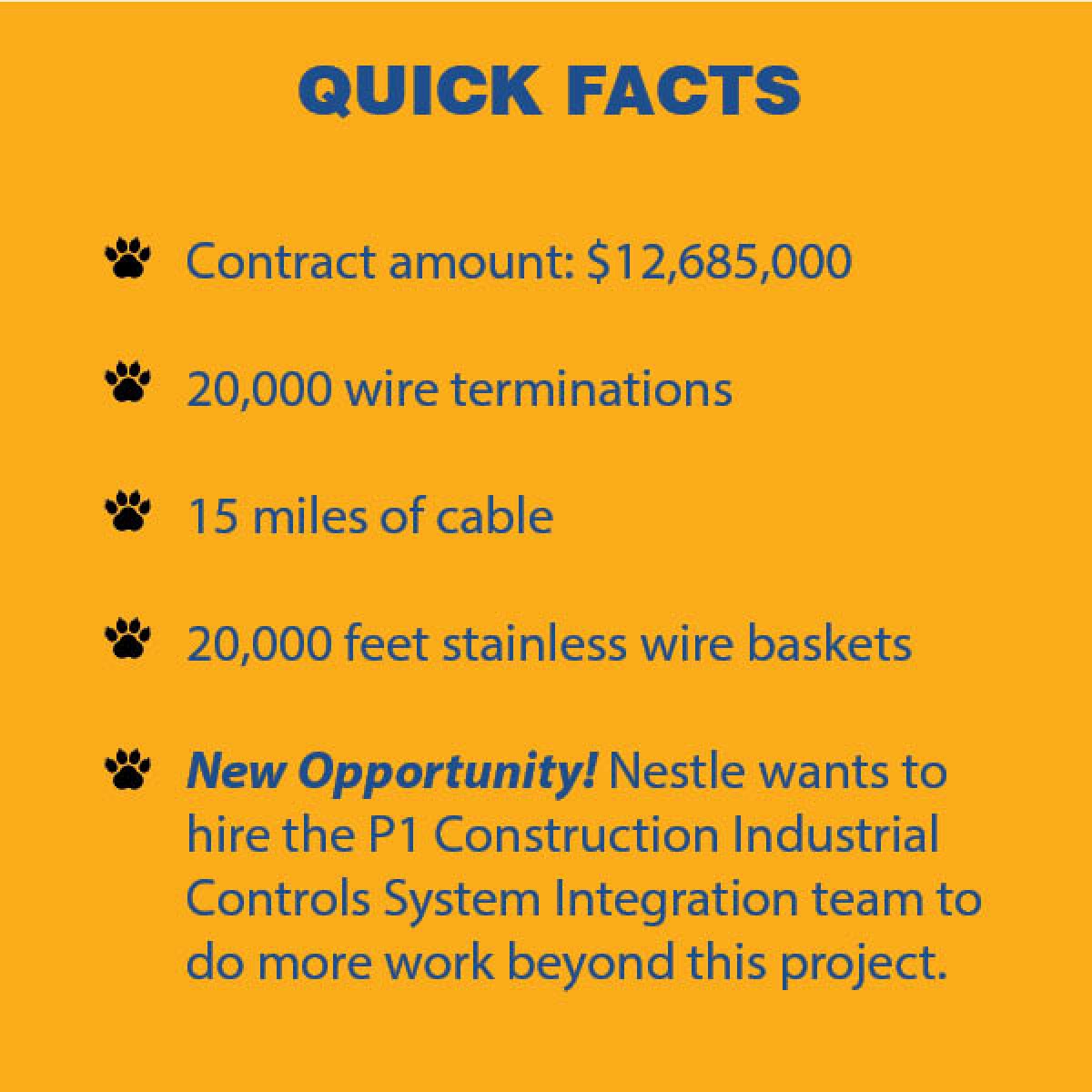

Shawn and Jason submitted the bid in August and were awarded the work for the Pennsylvania plant in October.

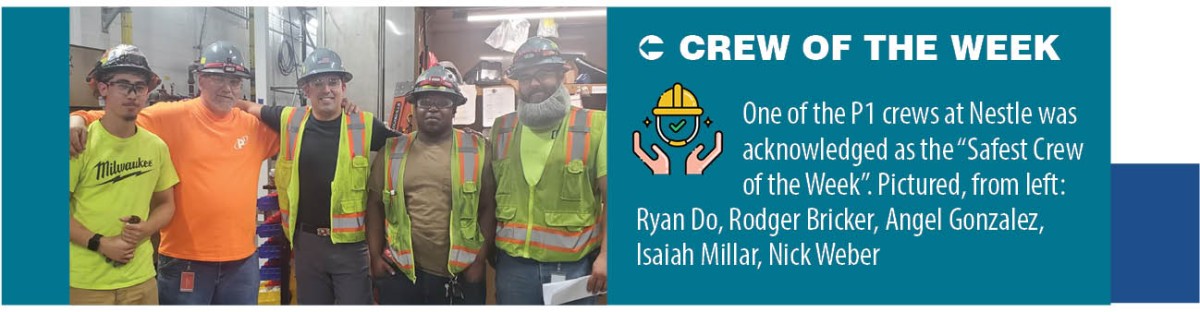

Shawn emphasizes how critical the field staff has been in creating the relationship with Nestle.

“When we received the contract, Nestle was very adamant that Foreman Mike Meyers be involved with the project,” Shawn said. “That speaks volumes about the kind of work Mike does. We are fortunate to have him as part of the team.”

Shawn says by the time P1 got the contracts in place, they were able to get the crew on site fairly quickly in November.

“We hired 25 people out of the local union in PA, but we have six foremen from IBEW Local 545 and LU 226 to handle the supervision and run the crew,” he said.

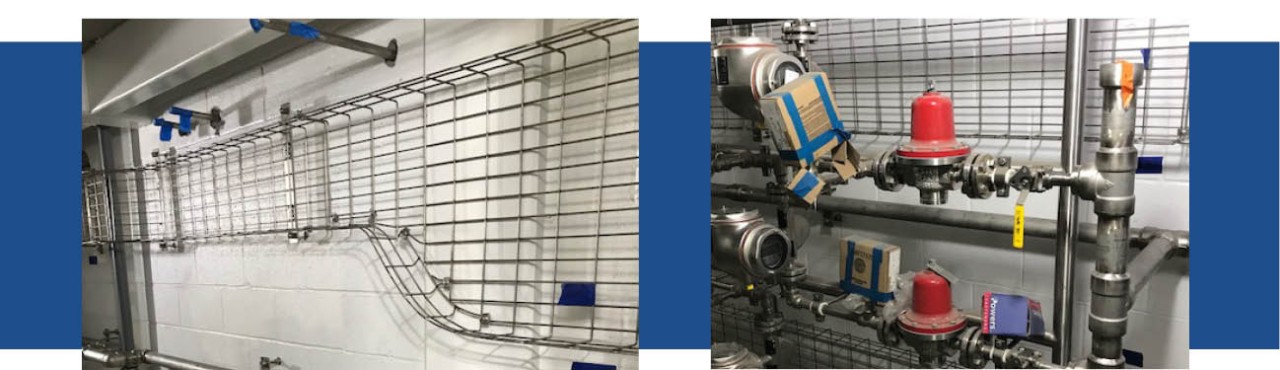

The project consists of upgrading an entire area of the plant by adding extrusion, drying, and wet blend equipment to increase production.

Shawn said supply chain continues to be an issue, but especially for the specialty materials needed on this expansion.

“This project required food-grade stainless steel wire mesh baskets, tray cables, and associated materials, which have been tough to procure. Lead times were horrible so we had to do a lot of juggling to get materials on site to get started and keep the project moving,” Shawn explained.

Because of P1’s single source capabilities, Nestle wanted P1 to do the entire project. Since all the pieces coincide closely, it would generate a more cohesive on-site execution.

For P1, this means handling all the electrical, with the sheet metal crew doing the stainless steel food grade welding, and the industrial systems integration controls division helping with controls I/O (input/output) checkout and start-up.

In addition, all sheet metal fabrication was done on site at the Nestle plant in Pennsylvania.

Shawn says the bulk of the project is complete, and the team plans to wrap things up by the end of August, utilizing just P1’s St. Joseph crew.

It’s no doubt the long-standing relationship between P1 and Nestle has generated opportunities, and the team looks forward to more on the way thanks to the consistent quality of work delivered by P1.

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.