Project Profile: Children’s Mercy Hospital Research Tower

What you don’t usually see when you visit a hospital are the massive mechanical systems behind the scenes that keep the environment precisely regulated, operations running smoothly, and patients and personnel safe.

In 2017, P1 Group was selected by General Contractor McCownGordon Construction for the mechanical scope of the two-part Children’s Mercy Hospital Research Tower project, also partnering with Engineer Brack and Associates and Architect BSA Lifestructures.

According to Project Manager Carey Minihan, one of the immediate project advantages was that P1 Group was selected early in the design process.

“We were able to work with McCownGordon, Brack and BSA to provide input on the design and receive feedback from the design team,” Carey said.

Carey says this collaboration allowed the team to customize the design around specific products (pre-fabricated exterior wall panels, CRC lab equipment and controls, dual-tunnel Temtrol air handling units, Johnson Controls).

“By doing this, many potential problems and obstacles were solvable during the early design phase,” Carey noted.

P1 Group was able to put its single-source value to work on this project, performing all of the following:

- VDC/BIM

- Detailing/Coordination

- Fabrication (Pipe/Plumbing/Sheet Metal)

- Construction (HVAC/Plumbing/Sheet Metal)

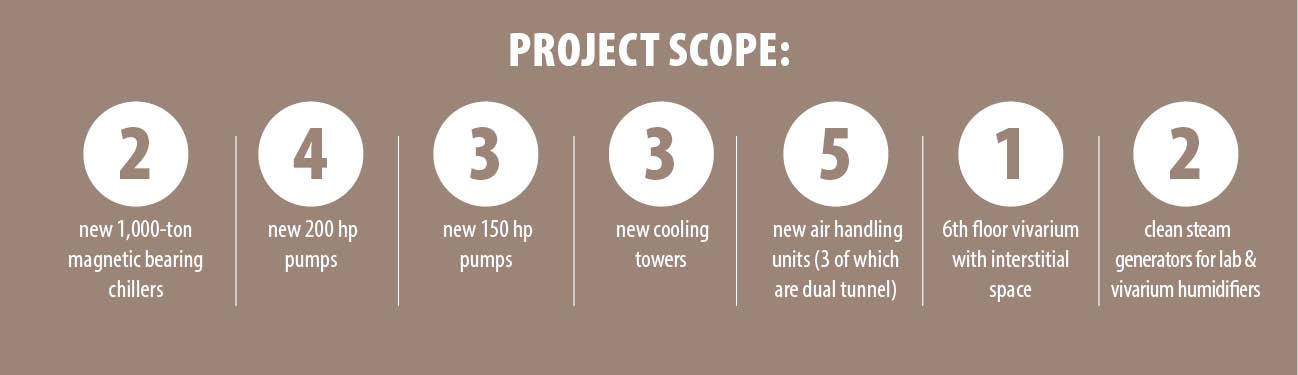

Phase 1 the project required the addition of 2,000 tons of cooling.

“Using the layout and design by our VDC department, we were able to prefabricate almost all of the new piping in our Lawrence fabrication facility,” Carey said.

During Phase 1, the chilled water piping was modified to turn two chilled water plants into one plant.

“One of the biggest challenges during the first phase was installing a new chilled water system and tying it into the existing chilled water system while the existing chilled water system continued to feed the facility,” Carey said.

“We used laser scanning to map the existing system and then our VDC department was able to route the new piping through the existing to make the new tie-ins.”

The cold winter made things more precarious when the team had to also navigate a one-day shutdown of the chilled water system on a very cold Saturday to make those tie-ins.

Phase 2 of the project, now in progress, is the construction of the new nine-story research tower along with a new auditorium.

The first two floors serve as office space, conference rooms, and other administrative spaces. Floors three and four are all laboratory space. The fifth floor is all mechanical.

Minihan said that one half of the sixth floor is a vivarium - a live ecosystem, usually enclosed, for keeping and raising animals or plants for observation or research - with an interstitial space in between. The other half of the sixth floor along with and floors 7, 8, and 9 are shell structure.

In Phase 2, VDC/BIM work will save time and labor.

“The key for us in Phase 2 is our VDC department’s ability to lay out and coordinate the new systems,” Carey said.

“Then we can install concrete inserts for all of our hangers (pipe and sheet metal) which saves a lot of labor - as opposed to drilling inserts. It also establishes the layout of the systems which saves layout time.”

The project is scheduled for completion in July, 2020.

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.