P1 Group Creates Packaging Line Automation Solution for CertainTeed

When it comes to large equipment, P1 Group’s Millwright team can fabricate and install some amazing solutions for customers like CertainTeed, manufacturer of building materials for both commercial and residential construction.

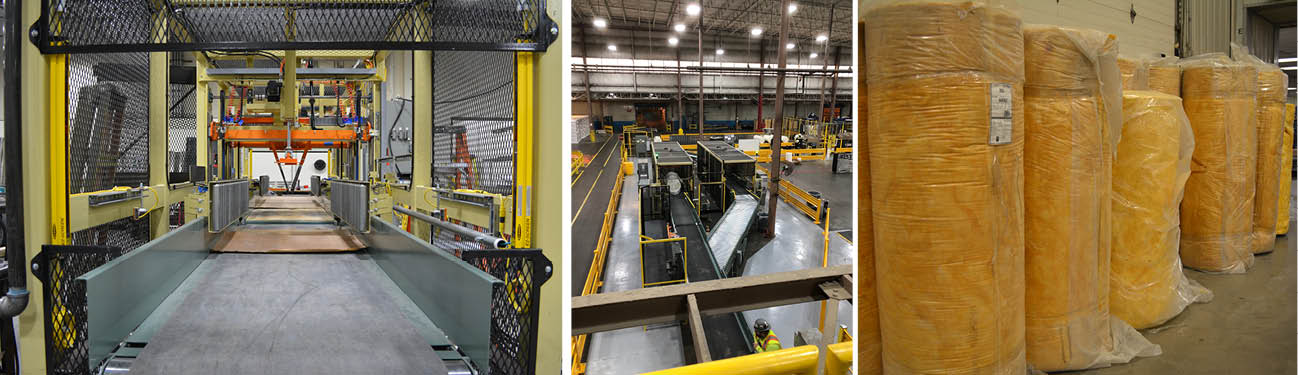

One product the CertainTeed plant produces in large quantity is roll-sealed insulation. P1 Group provided a turnkey solution to design, fabricate, and install two Metal Building Insulation Roll Sealers.

According to Senior Project Manager David McPherson, Design Engineering lead for the project, P1 was actually able to fabricate a solution that didn’t previously exist.

“The roll sealer P1 built in the Millwright Fabrication Shop is not a piece of equipment that existed prior to this project,” David explained.

“Several machines existed that did various portions of the work, but none in one unit.”

The sealers had to pillow seal both ends of a roll of insulation at a rate of three rolls per minute. Rolls range in size from 72”, 60” and 48” in length and 24”-26” in diameter and weigh approximately 100-125 pounds.

P1 Group Inc. also provided integration of all of the material handling conveyors from main product line, through the sealers, and finished with product delivery to stretch wrapping equipment in the warehouse.

The packaging line included belt, roller, and accumulation conveyors, and an automatic robotic roll placement cell, which transfers a metal building insulation (MBI) roll from a horizontal position on accumulation conveyors to a vertical position on stretch wrapping equipment.

"The entire project was part of automating a previously labor-intensive job,” David said.

“Prior, MBI rolls that can weigh up to 100 lbs. had to be manually bagged, sealed, and maneuvered into four roll bundles. These bundles were then gathered by fork trucks and placed into package-wrapping equipment.”

P1 Group’s fabrication and installation of the new “all in one” units not only makes things more convenient, it greatly increases safety at the plant by eliminating the ergonomic issue of handling heavy material and reducing the fork truck traffic in close proximity to workers.

QUICK FACTS

- Self-performed equipment installation, field electrical installation, mechanical piping installation and all engineering for the project.

- Quick-turn with purchase order awarded on May 28, 2019 and equipment start on December 18, 2019.

- Contract Value: $2,132,000

- Provided and Integrated vendor equipment for the project which included:

- (2) Automated Stretch Wrapping Machines

- (4) Automatic Labelers

- (1) Pick-and-Place Robot

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.