P1 Ford Air Tempering Project: Helicopter Pick and Crane Set Massive Equipment at Kansas City Assembly Plant

When looking at pipe, plumbing, ductwork, conduit, switchgear and everything else that goes into making a facility operate comfortably and safely, it’s easy to forget the end beneficiaries of those items are the people who use that facility every day.

P1 was awarded a design-assist role with Roncelli, Inc. for the air tempering project at the Kansas City Ford Plant in Claycomo, MO. The project will create more regulated temperatures inside the plant, benefiting workers and equipment, especially in summer months.

According to P1 Director of Preconstruction Don Erisman, the project was procured as a design assist project with Roncelli Inc., Ford, and the design team.

“The project consists of furnishing and installing approximately five miles of chilled water piping ranging in size from four (4) inch to twenty-four (24) inch,” Don said.

The majority of that piping is fusion welded polypropylene pipe located on the roof of the Ford plant.

Don notes that the project included the receipt and refurbishment of several massive heating and cooling units.

“The scope is inclusive of receiving two (2) 170,000 cubic feet per minute (CFM) heating and cooling units and setting them on the roof of the body shop of the plant. The scope will also include refurbishing eleven (11) air handling units ranging in size from 45,000 CFM to 170,000 CFM located on the main plant” Don said.

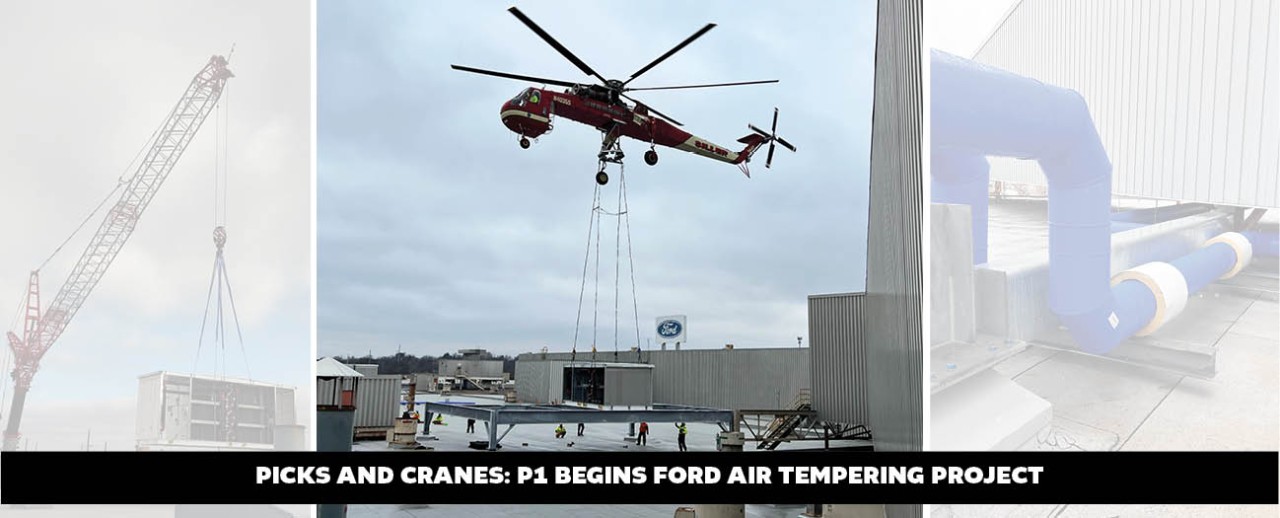

The two 170,000 CFM units were hoisted to the roof using Wilkerson Crane’s 770-ton crane. The lifts were on different sides of the Truck Body Shop, which required setup and tear down in each location.

Also included will be the addition of chilled water coils, new supply fans with VFDs, plenum extensions, and service vestibules for several existing heating-only air handling units.

Senior Project Manager Rick Ellis notes how the project team took advantage of the plant’s holiday shutdown between Christmas and New Year to set all of the equipment by helicopter pick.

“There were twenty-seven (27) picks in one day, which required extensive coordination efforts between P1, the plant and the general contractor,” Rick said.

Even with snowy weather and cold temps, the picks were successful in getting all items safely to the roof and set in place.

The project is in progress now and is scheduled for completion this summer.

Quick Facts

- Design-Assist

- Contract Amount: $23M

- GC: Roncelli

- Engineer/Architect: Gala

- Two (2) 170,000 CFM heating and cooling units

- Eleven (11) 45,000 CFM to 170,000 CFM air handling units

- Five (5) miles of chilled water pipe, 4 - 24 inch

Team

- Preconstruction/Design Assist: Don Erisman

- Team Leader: Jason Quattlebaum

- Senior Project Manager: Rick Ellis

- General Foreman: Cole Mescher

- Foreman: Dan Head

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.