Kindred Bio Expansion Showcases Capabilities

P1 Group’s Kindred Biosciences Production Expansion project was born from customer relationship building and a solid example of P1 teamwork across many trades and services.

KindredBio, a pet biopharmaceutical company based in San Francisco, took over an older pharmaceutical manufacturing facility in Elmwood, KS, and will soon manufacture drugs there for companion animals like cats, dogs and horses.

“This is a pharmaceutical facility that is very intense on process – both mechanical and electrical – so it really fit our wheelhouse,” Vice President Glenn Shain said.

He also noted P1 Group had completed a great deal of work at the site for the building’s previous owners, so we were able to get started, fast, installing underground plumbing and stainless steel process waste before there was a sketch.

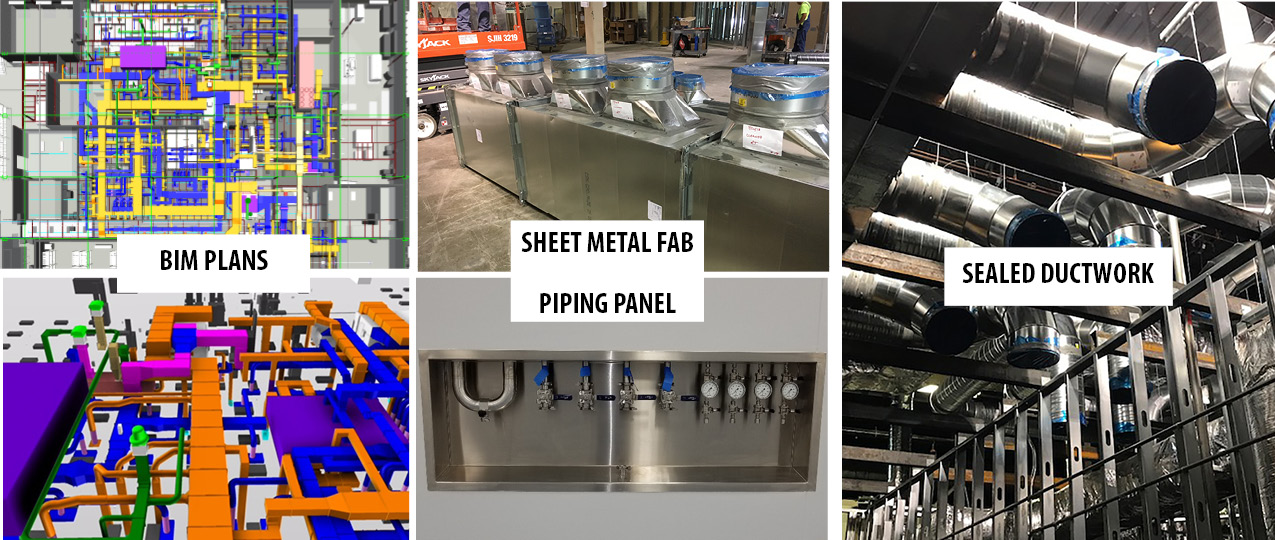

HVAC, piping and electrical trades (field and shop) all completed work for the expansion. P1 Group’s Performance Solutions team stepped in because the project required design assist. The startup is finished and the project is now in the commissioning equipment stage.

P1 Group’s VDC team had a critical role in delivering this project on time and within budget. They worked from CRB’s engineering documents to create a highly technical model that fit significant ductwork, piping, conduit, and wire in a tight space.

The facility’s requirements for absolutely clean duct and piping also presented a challenge. For example, the facility required nearly 62,000 pounds of ductwork. After it was fabricated and shipped to the site, completely cleaned and sealed, Paul Spicer, sheet metal foreman, said his team took extra steps to keep the duct clean.

“When we got it off the truck we checked to make sure it was still sealed and then kept it sealed all though the install,” Glenn said.

Other specialized piping and systems included ambient WFI water, hot WFI water, oxygen, carbon dioxide and compressed air. These systems had to be installed per ASME Bioprocessing Equipment Standards, which required P1 to have a complete QA/AC program in place to install and validate the systems.

P1 Group’s diligence on the project delivered the finished and expanded facility on time to KindredBio, who is now awaiting validation from the USDA to begin manufacturing drugs.

Animal Pharm, an industry publication, recently named KindredBio “Best Company in North America,” noting an impressive 20 drugs that KindredBio has under development - mostly notably Mirataz, which treats anemia and weight loss in cats.

Key Project Personnel

Project Executives: Glenn Shain and Kollin Knox

Project Managers: Jason Quattlebaum, David Sall, Blane Sumers, Cris Ray, Chuck Huff

Foremen: Paul Spicer, Will Wall, Randy Park, John Mularoni

Fabrication Foremen: John Kraus, Jeremy Price, Michael Wessel

VDC: Ted Thompson, Nate Littlejohn, Tom Taylor

Startup and Commissions: Adam Collier, Aaron White

Performance Solutions: Bill Frede, Alan Sparling, Rusty Roderick

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.