Going Trenchless: P1 Las Vegas Offers Trenchless Replacement of Underground Pipe Infrastructure

The P1 Las Vegas team took the company’s commitment to offering “single source” solutions to a new level recently, adding another capability to the list: trenchless pipe replacement and repair.

The trenchless piping method has become popular because it’s cost-effective, lasts a long time, and causes minimal property damage.

According to General Foreman Mario Vitale, P1 has been using this piping method for several years, but always went through a subcontractor to do the work.

Recently, that subcontractor went out of business, leaving P1 in a dilemma.

“We either needed to find another qualified subcontractor or make the investment to do the work in-house,” Mario said.

Mario said the initial monetary investment was substantial, but the return on investment is well worth it. Bringing this capability in-house came in two parts: The first was securing the right equipment for the job, which included long lists of lining, epoxy coating, bursting, and point and sectional repair equipment.

The second part was hiring an expert: P1 hired Trenchless Foreman Wyatt Martin. Wyatt previously worked for the subcontractor P1 used in the past, so he has extensive experience and knowledge with this piping method.

“Trenchless is a great tool to have in your toolbox. Most of our work does not does not require the facility to shut down operations or INCUR large flooring repair bills like traditional trenching would.” -Trenchless Foreman Wyatt Martin

PICTURED ABOVE, TOP ROW: internal view of a 10-ductile iron line in which the team installed a fiberglass point repair; internal view, seal of the lateral piping of a 6 x 5 combo fitting lined at Cimarron HS; internal view of epoxy line at Green Valley HS; BOTTOM ROW: Las Vegas Special Projects Team

Once equipment and personnel were in place, P1 hit the ground running, rehabbing approximately 5,000 feet of pipe in just the past four months.

P1 is currently the only union mechanical contractor in Nevada doing this piping method in house.

Recent projects include University of Nevada-Las Vegas, Cimarron High School, and Silverado High School.

According to Wyatt, the process is particularly attractive to schools.

“Schools are our main customers due to modernization projects,” Wyatt said. “This process is more appealing due to the low impact on the facility, compared to traditional dig-and-replace.”

Wyatt explained that utilizing fewer excavations, P1 can perform the rehab/replacement of the underground from within the piping.

“We can rehab or replace hundreds of feet of piping running through classrooms without those rooms being affected. We can also utilize these technologies for in-wall piping,” he said.

“For example, we perform epoxy coating from the roof penetration of the vent piping to the connection to the underground piping.”

Wyatt notes the payoff for the owner is saving them the expense of wall replacement and cabinetry, and saving staff and students the inconvenience of having their space disrupted.

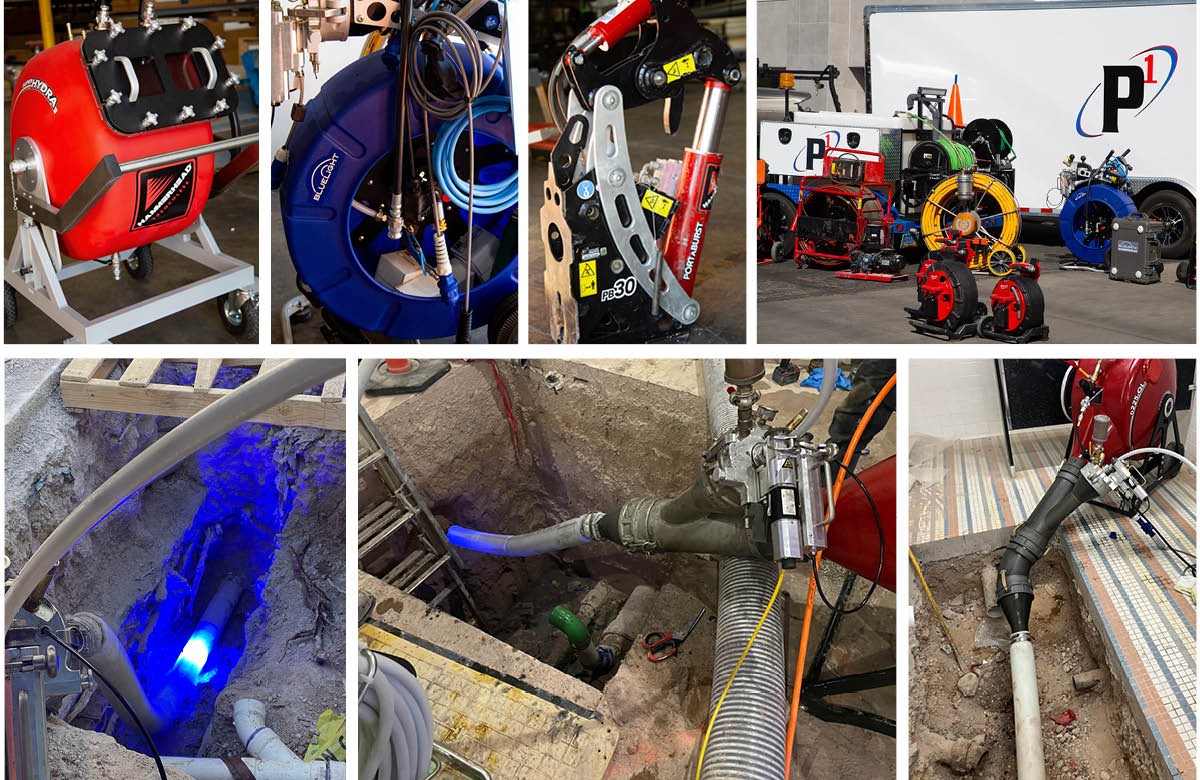

PICTURED, TOP ROW: Some of the necessary equipment, including composite inversion drum, Bluelight LED for cured-in-place piping (CIPP), Portaburst for lateral bursting; PICTURED, BOTTOM ROW FROM LEFT: 1 and 2: pipe liner cured with a blue light at Silverado High School; installing a four-liner in a cast iron line at Knudson Middle School.

In addition to schools, the process works on large scale projects as well, including casinos and civil projects.

“Trenchless is a great tool to have in your toolbox due to the low social impact it creates,” Wyatt said. “Most of our work does not require the facility to shut down operations or require large flooring repair bills like traditional trenching would.”

Mario said there are several methods and procedures that can be used, and that is determined by the type of piping that needs to be repaired or replaced. The trenchless method can be done on any type of piping, including sewer, drainage piping, pressure piping, chilled water, hot water, domestic water, and even electrical conduit.

“If it’s piping, we can fix it,” Mario said.

He notes lining and epoxy coating technologies are used most often, as they are the least impactful. Bursting is also a good method of pipe replacement since it doesn’t require excavating the entire pipe length.

“For pipe bursting, a cable and winch pull a hydraulic or pneumatic expansion head through the existing pipe, forcing it outward until it breaks,” Mario explained. “The new pipe is then pulled through the broken pipe to fill the void.”

“Pipe bursting is quick, quiet, and doesn’t require city permits,” he added. “It’s also considered sustainable because it doesn’t use chemicals or contaminants, and the new pipes are made from environmentally safe, high-density polyethylene (HDPE).

“Epoxy pipe lining, also known as cured-in-place pipe (CIPP) lining, is a minimally invasive process that creates a new pipe inside an existing pipe. The epoxy liner is placed inside the pipe and cured with blue light,” he said.

Mario noted epoxy pipe lining can be used on pipes of any size and can be a good option for repairing piping systems without disturbing the landscape or architecture.

Cheers to the Vegas team on executing efficiency for our customers!

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.