P1 Virtual Design and Construction Stays on the Cutting Edge of Technology and Customer Service: And Customers are Noticing

Improving operations through strategic initiatives is great, but it’s even better when your customers see – and talk about – the positive effect your efforts are having.

P1’s Virtual Design & Construction (VDC) division is experiencing just that, with recent feedback from general contractors on major P1 projects.

According to VDC Manager Bret Faris, the team continues to upgrade technology and processes to produce the best results.

“Our team is committed to delivering efficiency through technology, procedure, and communication,” he said.

VDC Plumbing Supervisor Joe Barajas spends time both in the office and in the field, helping ensure communication runs smoothly throughout the project.

“The VDC department handles far more than just the constructability - we touch all facets of a project, from start to finish” Joe said.

He notes that from the customer/owner kickoff through execution of a construction project, the P1 VDC team is a critical collaborator.

“The entire multi-trade VDC team works together using the latest technology, and provides ongoing partnership throughout the life of a project to ensure accuracy across all stages,” he added.

Bret notes that communication efforts begin early in the project.

“We facilitate coordination with the general contractor, trade partners, and engineering team, and then distribute key information to the project manager, foreman, fabrication team, and others,” he said.

“We’ve been able to grow by seeking and understanding feedback,” Joe added. “We try to talk with project managers to learn what we did well, and where we can improve.”

Productivity through Technology

The technology the VDC team invests in may not be obvious out in the field, but it is probably the greatest contributing factor to efficiency and accuracy.

“In order to be the best at what we do, VDC continues to evolve our processes - including software,” Bret said.

VDC Specialist Richard Anderson explains the transformational transition from Revit Families (.RFA) to Fabrication Parts (.ITM).

“Our plumbing and piping teams have moved from Revit Families (.RFA) to Fabrication Parts (.ITM). This allows P1 to own and manage its BIM database, which contains all of the pipe, fittings, and accessories used to detail each project VDC works on,” he said.

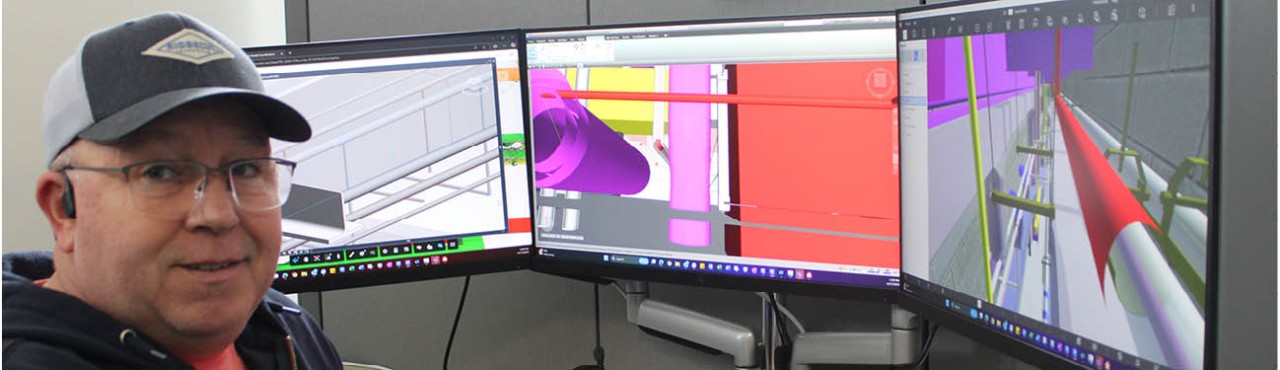

Plumbing VDC Specialist RG Stewart uses time-saving technology to work on VDC drawings.

“This ownership means we can standardize processes across projects, ensure consistency in our outputs, and rapidly implement improvements to our workflow.”

The end product is providing P1 off-site construction shops with only the information needed to fabricate efficiently.

Richard also notes that Revit add-ins like Guardian allow the team to deploy project standards with the click of a button, shortening project setup times by 50 percent.

P1 Construction Technology Manager Jeff Peterson explains how that translates through the life of a project.

“Harvesting data on the back end of fabrication establishes a high level of consistency,” Jeff said.

“This means we can track components throughout the project lifecycle, ensuring that what was designed is what gets built, and what gets built is what was planned.”

INDUSTRY ALIGNMENT

P1 VDC has been utilizing the Autodesk Construction Cloud - also known as ACC (and formerly known as BIM 360) - for nearly a decade.

This cloud-based platform allows P1 to host its BIM projects on the cloud, saving countless hours.

“We are seeing more general contractors use this space to run their VDC operations with trade partners,” Richard said. “In addition, P1’s operations team has come aboard using the Build module in ACC, which conveniently hosts contract drawings, 3D coordination models, project photos, project forms, RFIs, and submittals.”

Jeff says the technology growth keeps P1 competitive.

“Moving to ITM content aligns P1 with the standards in the mechanical fabrication industry,” he said.

“This alignment not only improves our ability to collaborate with partners like Southland on Project Kansas, but also ensures we’re part of driving the industry’s future technological development.”

General contractors have rated the VDC team with five-star reviews across multiple performance indicators, including communication, technology and trade expertise, problem solving, deliverable dates, and meeting attendance.

“I was very impressed with P1 when it came to the BIM coordination for this project. They were always on top of things and I never had to worry about whether they were doing what needed to be done. Would be happy to do more projects with P1.” -JE Dunn/AdventHealth Cancer Center

“We couldn’t have done this project without the P1 BIM team. They were knowledgeable, very professional, and very patient. This was a long, challenging project. At every meeting, P1 was present and working hard to complete coordination.” -McCownGordon/Garmin Building 1 Renovation

“Project Sandhills is a large and complex MEPF project that had heavy coordination and VDC efforts. The P1 BIM team did a great job taking the lead and helping push the pace of the project. P1 was timely in responses, and persistent on follow-ups. P1’s efforts helped ensure a smooth process from VDC to field procurement, it was much appreciated.” -McCownGordon/Project Sandhills

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.