Project Profile: Cleveland University HVAC Improvement Project

When teamwork happens the way it is supposed to, it can produce incredible things. This was demonstrated by the large team that pulled together for the multi-phase HVAC improvement project at Cleveland University. Not only did the customer get a top-notch product, the project illustrates the benefits of working with a single-source provider.

P1 Service prides itself on long-term customer relations, and few have been as long as the relationship with Cleveland University (formerly Cleveland Chiropractic College).

P1 has had a 20+ year preventive maintenance contract with Cleveland University, making them what Vice President of Service Stuart Sherrow considers a “customer for life.”

In 2008, the University moved to its current 34-acre location in Overland Park. Even though the grounds and buildings were a vast improvement from the former location, the University immediately recognized the need for extensive mechanical system upgrades.

P1 Service’s Performance Solutions team developed a multi-phase plan for building improvements, also leveraging our in-house engineering, MEP, fabrication, and controls resources.

Phase one of the multi-phase master plan started with the heart of the system: the boiler and chiller plant, pumping systems, cooling towers and controls upgrade. This phase was completed in 2014 and these upgrades have provided quieter, more reliable and energy efficient equipment, resulting in lower operating and repair costs for the University.

Phase One of the project, completed in December, 2014.

Phase One of the project, completed in December, 2014.

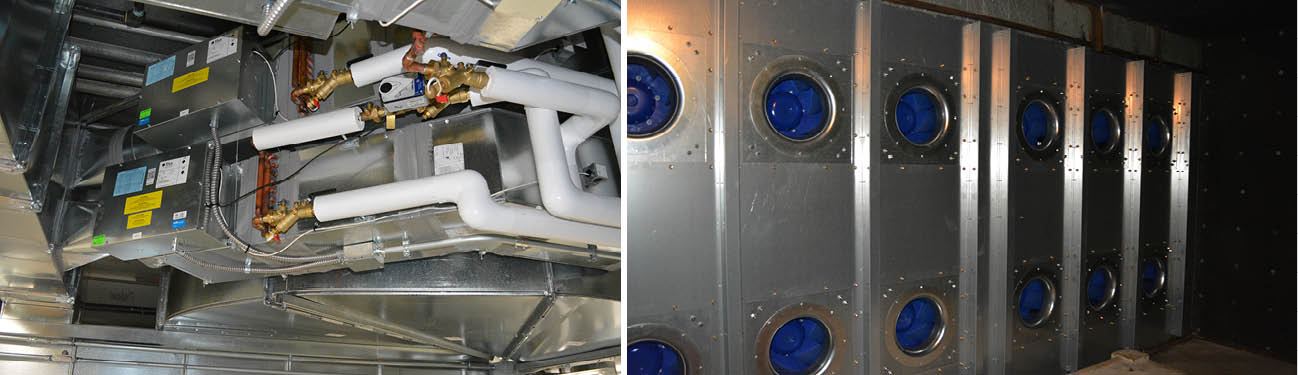

Phase two began in December 2018. This phase consists of upgrading heating water coils and chilled water coils, ECM fan arrays for supply and return fans on all air handlers, removing the old pneumatic control system and installing state of the art DDC controls with web-based software.

The air handler upgrades were scheduled to be done during the University winter and spring breaks. Due to short time frame for both of these installs, pre-planning and execution had to be precise.

According to Lead HVAC Technician Ryan Rotterman, project management was key.

“Zach Kittle did an excellent job with the project management to ensure that all aspects of the project ran smoothly,” he noted.

Ryan also noted one of the many challenges this project presented was the size of the equipment involved.

“In order to bring equipment that large in and out, the third floor of the building was opened up to the outside by removing the air louvers, and hoisting equipment was used to remove old equipment and put new equipment in place,” Ryan said.

The original air handlers consisted of one large fan (approximately 6 ft. square). These fans were dismantled and replaced with numerous smaller fans that each work independently, ensuring continual air flow should one of the fan motors become disabled.

During this process, the building was open to the outside elements, so the crew set up temporary heating units to keep the building from freezing.

Spring break only allowed the team a total of nine days to completely replace two air handlers, associated piping, duct work, VAV boxes, electrical, controls, and start-up. The Student Chiropractic Clinic was open part of the week and that was the main access to the work area, which added the challenge of working around the patients and doctors.

Another demanding aspects of this project was the ductwork. During both shutdowns in phase two, fan arrays were installed in the air handlers and all the duct work had to be custom made by the sheet metal shop.

Gunnar McCartney, Sheet Metal Foreman, had the monumental task of mapping out and fabricating all the ductwork that was required to fit in the small space. Gunnar measured each section and called in the specifications in to the fab shop in Lawrence, where the pieces were fabricated, sent to the job site, and installed.

According to all involved, this project took a great deal of orchestration and would not have been possible without the teamwork and cooperation of the entire team.

Proposals have recently been submitted for next phase of upgrades, and P1 Service plans to continue providing Cleveland University with quality mechanical solutions and service, for life.

Project Team

- Project Design/Engineering: Rusty Roderick, Bill Frede, Alan Sparling

- Project Manager: Zach Kittle

- Startup: Ryan Rotterman, Kyle Cullen, Mike Bolger

- Pipefitter Foreman : Cole Mescher

- Controls: Justin Foster, Danny Addadi

- Sheet Metal: Gunnar McCartney, David Wright

- Electrical Installation: Josh Chandler, Keith Everhart

- Test and Balance: John Cobb, Bob Pasquarette, Kevin Colvin, Rachel Toney

About the author

P1 Service, LLC is a single-source specialty service subcontractor providing comprehensive facility solutions while always striving to enhance the customer experience. We are a trusted partner throughout the Midwest for single-source facility maintenance solutions, including HVAC, electrical, and plumbing facility maintenance and service.