P1 Electrical Service Team Takes on Giant Generator Refurb for AECI

Green Energy Creates Big Opportunity for P1 Electrical Preventative Maintenance Team

When Associated Electric Cooperative Incorporated (AECI) needed to add capacity to their grid by making use of some idle generating equipment, the P1 Electrical Preventative Maintenance team was the one for the job. AECI had two 20 megawatt generating stations, each measuring 18’ long x 12’ wide by 12.5’ tall, and weighing 28,000 lbs. These units act as small powerhouses that supply a little extra boost when the demand on the grid is high.

AECI is in Springfield, MO, although the Generator Accessory Compartments (GACs) reside in AECI’s Unionville, MO power generating station.

The GACs provide power generation and high-voltage transmission to six transmission co-ops. They supply 51 local electric cooperatives in Missouri, Iowa and Oklahoma serving about 935,000 homes, farms, schools and businesses.

AECI relies on a mix of generating resources and technologies to deliver electricity and balance that mission with hydropower when it’s available, then coal, natural gas and wind energy.

Due to the closure of coal-fired power plants, AECI needed to find ways to add additional capacity to the grid and decided to make use of some idle equipment.

On site they had two 20 megawatt generating stations, measuring 18’ long x 12’ wide x 12.5’ tall and weighing 28,000 lbs. These units act as small powerhouses that supply a little extra boost when the demand on the grid is high. They were brought online in the 1970s, decommissioned in the 1990s, and have been dormant ever since.

The project to refurbish these units went out to bid and AECI didn’t have anyone in mind for the work, but through a former co-worker of P1 Project Engineer Wade Buck, P1 got the recommendation, and subsequently joined late in the bidding process.

According to Electrical Preventive Maintenance Manager Jeff Gardner, it was a herculean effort just to assemble the bid.

“There were a lot of components that needed pricing in addition to a plan for execution and a project schedule. We relied on a lot of internal resources to help with that,” Jeff said.

Jeff also mentioned that one of the key factors for being awarded the project was having the support of experienced negotiators, including P1 Vice President Tony Whited, P1 Vice President Rusty Roderick, and P1 Service President Phil Nehring.

“It was great to see them in action and see how they got excited for an Electrical Preventative Maintenance (EPM) opportunity,” Jeff noted. “It was clear they have been through many negotiations like this before, so it was a unique learning opportunity for Wade and myself.”

And P1 dazzled the customer, earning us the bid.

Once the contract was secured, the first order of business was to get the units moved into the Lenexa warehouse. Due to the size and weight of the units, Belger Cartage Service was used to pick the units off of a trailer with a crane and roll them into the warehouse.

After the units arrived on site, a detailed inventory of the contents was taken and catalogued, and then the contents were removed. The outer shell will be taken to a painting contractor.

The current color is gray, but it will be restored to the original sea foam green, giving it a vintage 70s flare with state-of-the art components when complete.

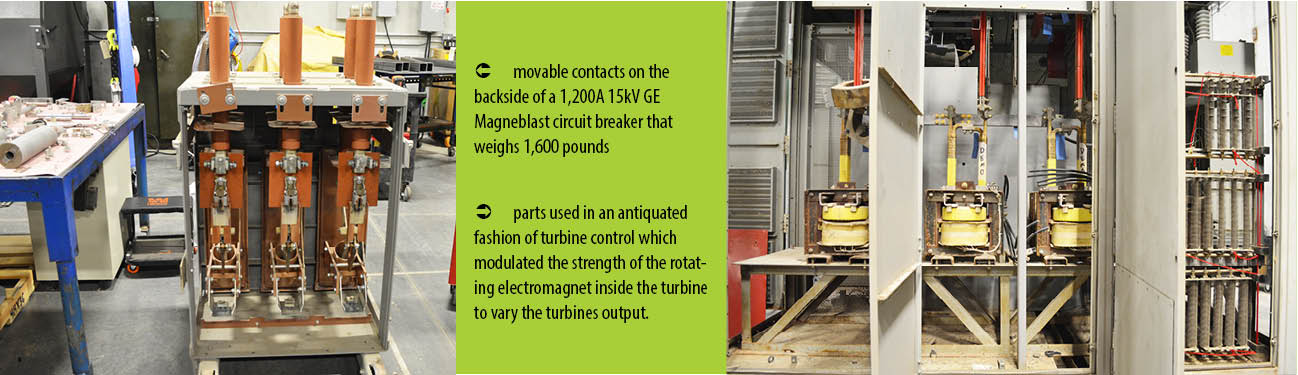

Jeff says a significant part of this project is the refurbishment of two very large breakers.

“We wouldn’t be able to service this opportunity if we didn’t have the Breaker Shop and the staff with superb skills and expertise,” Jeff said.

He says the Breaker Repair Shop, developed last year and located in the Lenexa warehouse, was a fortuitous investment because it paved the way for a big opportunity like the AECI job.

“As this project gets underway, the team is excited about it, and you see everyone’s unique skill sets working together toward a common goal. This project really is the perfect demonstration of The Expertise of Many, The Power of One.”

PROJECT TEAM

Zach Wilburn: Project Lead/Field Oversight

Allen Hulett: Technical Lead

Wade Buck: Project Manager

Jeff Gardner, Electrical Preventative Maintenance Manager: preparing the warehouse

Phil Nehring, P1 Service President: proposal development/negotiation strategy

Tony Whited, P1 Service Vice President: proposal development/negotiation strategy

Rusty Roderick, P1 Service Vice President: negotiation strategy

Laura Adkins, Project Coordinator

About the author

P1 Service, LLC is a single-source specialty service subcontractor providing comprehensive facility solutions while always striving to enhance the customer experience. We are a trusted partner throughout the Midwest for single-source facility maintenance solutions, including HVAC, electrical, and plumbing facility maintenance and service.